On-Site Mixing for Jobs That Don’t Fit a Fixed Schedule

Not every concrete job can be measured perfectly in advance. Site conditions change, quantities shift, access becomes limited, and pours often happen in stages. Volumetric concrete delivery is designed specifically for those situations.

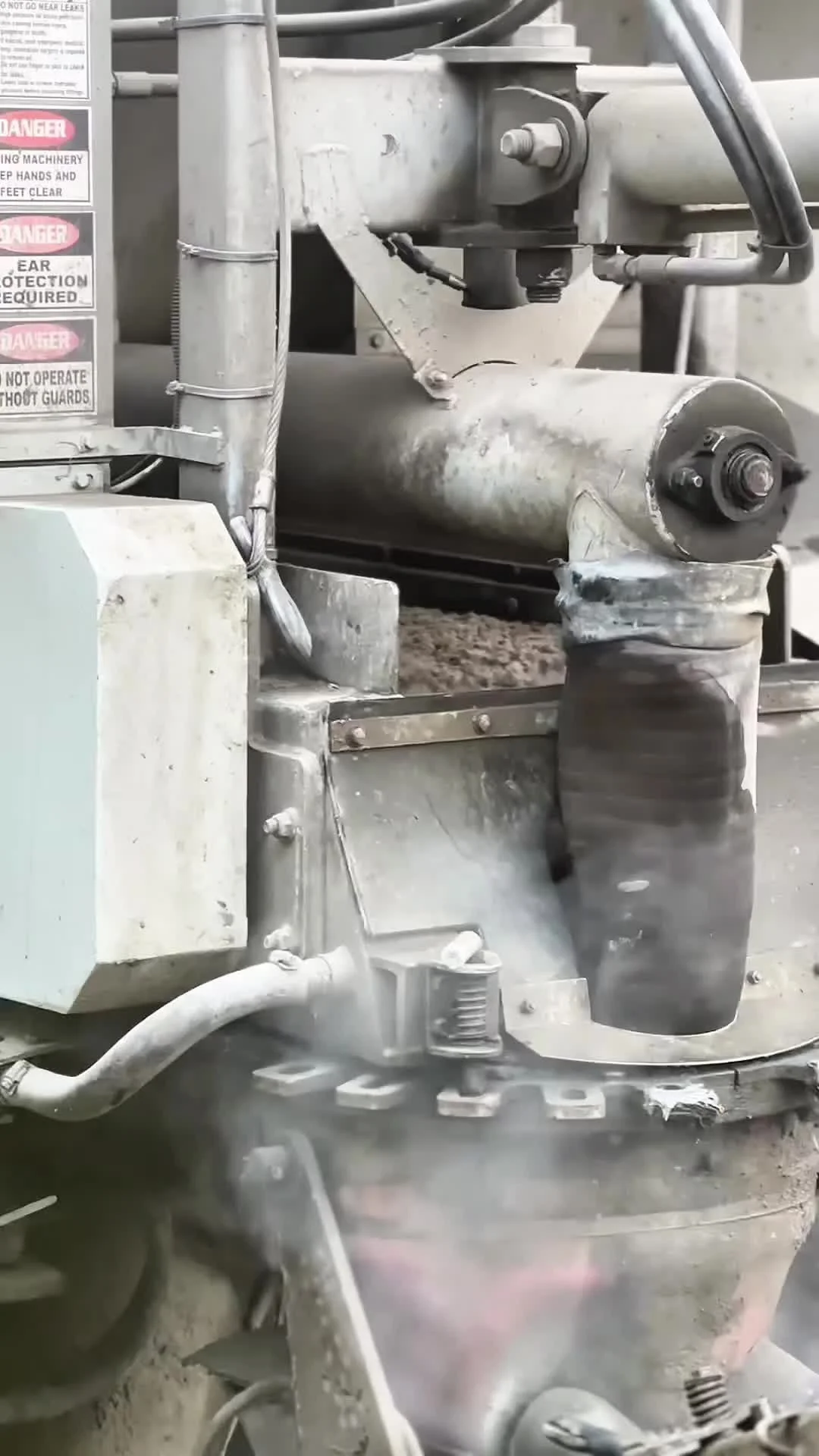

Instead of arriving pre-mixed, concrete is produced directly at the job site. Materials are stored separately and blended as needed, allowing crews to control volume, strength, and consistency in real time.

How Volumetric Concrete Works on the Job Site

Volumetric trucks carry cement, aggregates, sand, water, and admixtures in separate compartments. Mixing happens on demand at the point of placement, not before arrival.

This allows concrete to be produced:

In exact quantities as the pour progresses

With adjustments made mid-job if conditions change

Without concerns about time limits from central batching

Concrete is placed fresh, immediately after mixing, which helps maintain workability and consistency throughout the job.

When Volumetric Concrete Is the Right Choice

Volumetric delivery is commonly used on projects where quantities are difficult to predict or where pours are completed in phases. These include:

Footings and foundations with variable depths

Repairs, extensions, and additions

Residential slabs, pads, and walkways

Landscaping and hardscape installations

Pool bottoms, curbs, and steps

Jobs with tight access or limited space

This method allows crews to pour exactly what is needed without committing to fixed volumes upfront.

Who Is This Service For?

Our volumetric concrete delivery is ideal for:

Homeowners planning driveways, walkways, patios, or garage slabs

Contractors and builders working on foundations, curbs, sidewalks, stairs, retaining walls

Municipal and industrial projects requiring specialized mixes

Wherever you’re located in the Greater Toronto Area, we deliver on-time and with precision.

What Can Be Mixed On-Site?

We offer a full range of mix designs:

10 MPa Ultra Base (for under interlock)

Standard mixes: 15 MPa, 20 MPa, 25 MPa, 30 MPa, 35 MPa

High early strength mixes: 30, 32, and 35 MPa

Pea gravel mixes for floors or exposed aggregate

Grout (1:1 to 1:4)

Drypack for tile and marble

U-Fill and engineered backfill

Air-entrainment, fiber reinforcement, and other admixtures available.

Adjusting Strength, Slump, and Mix Design On Site

Ideal Applications for Volumetric Concrete Delivery

Volumetric concrete is not a one-size-fits-all solution. It excels in applications where flexibility, accuracy, and timing are critical.

Common uses include:

• Foundations and footings

• Structural slabs and pads

• Pool bases and specialty pours

• Utility trenches and U-fill applications

• Municipal and city infrastructure work

• Projects requiring multiple mix designs in one visit

• Jobs with limited access or extended placement times

• Winter concrete pours

For projects with uncertain quantities or phased placement, volumetric delivery removes the risk of ordering too much or too little concrete.

One of the defining features of volumetric concrete is the ability to fine-tune the mix during the pour. Adjustments can be made to account for:

Reinforcement density

Temperature and weather conditions

Finishing requirements

Specific applications such as grout or U-fill

This level of control is especially valuable when conditions vary across a single job site.

Service Areas

We proudly deliver volumetric concrete to:

Toronto, North York, Scarborough, Etobicoke

Mississauga, Brampton, Vaughan, King City

Markham, Pickering, Oshawa, Aurora, Richmond Hill

And all surrounding cities in the GTA & York Region

Access-Friendly Delivery for Challenging Sites

Because concrete is mixed at the point of discharge, volumetric trucks are often used where:

Space is limited

Access is restricted

Multiple placements are required across a property

This makes them ideal for residential neighborhoods, tight urban areas, and projects that require careful staging.

FAQs

-

Volumetric concrete delivery is a method where concrete is mixed directly at the job site instead of being pre-mixed at a batch plant. The truck carries raw materials separately and produces concrete as it’s needed. This allows for precise volume control, fresh concrete placement, and the ability to adjust strength or consistency during the pour based on site conditions.

-

Volumetric concrete is ideal for projects where quantities are difficult to estimate, pours are completed in stages, or site conditions may change. It is commonly used for footings, foundations, slabs, walkways, repairs, landscaping projects, and jobs with limited access. On-site mixing allows crews to pour exactly what’s needed without short loads or excess waste.

-

Yes. One of the main advantages of volumetric concrete delivery is the ability to adjust mix design on site. Strength, slump, and certain mix characteristics can be modified during placement to suit the application, weather conditions, or finishing requirements. This level of control helps ensure the concrete performs as intended for the specific job.